This is the most commonly used material due to its low cost. It can be easily toughened to effectively increase the mechanical strength of annealed glass by up to five times.

We have plant and equipment, including our water-jet cutting machine and CNC machining center.Quartz glass according to customer's requirements, made from JGS1, JGS2, JGS3, on production.

Borosilicate glass according to DIN 7080.

For compressive stress with temperatures borosilicate circular sight glass up to max. 280 degrees Celsius,

Where a greater degree of chemical resistance or higher operating temperatures are required, a borosilicate glass should be specified. In a toughened form, temperatures up to 315 degrees Celsius are possible whilst annealed glass may be used up 400 degrees Celsius continuously with a short term maximum of 500 degrees Celsius.

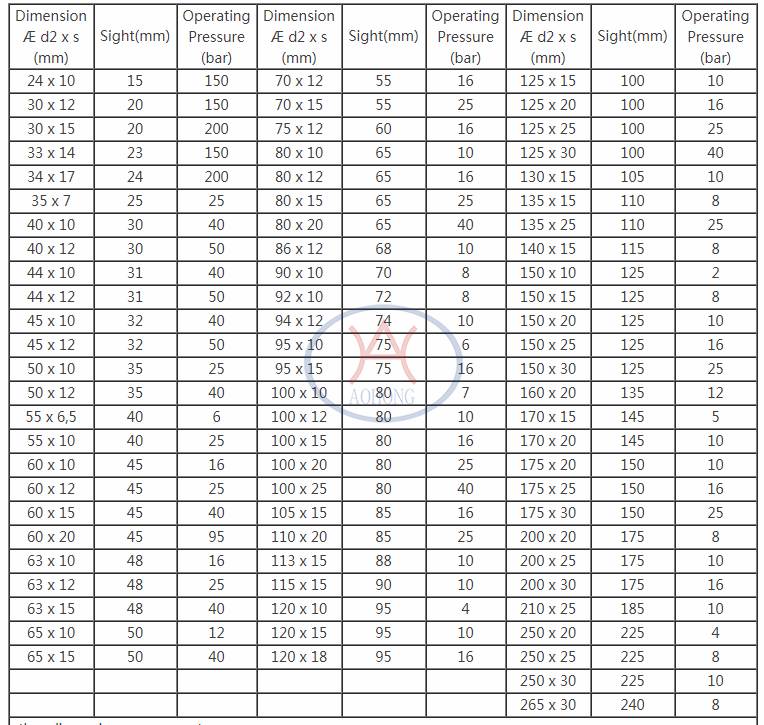

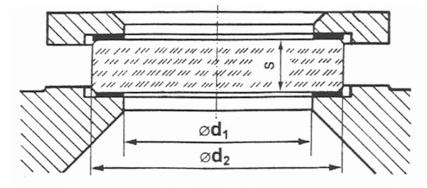

In addition to standard DIN sizes, glasses are available in a wide range of diameters up to 60mm thick (see annular edge sight glass).

Soda Lime glass according to DIN 8902.

For compressive stress with temperatures borosilicate circular sight glass up to max. 150 degrees Celsius,

This is the most commonly used material due to its low cost. It can be easily toughened to effectively increase the mechanical strength of annealed glass by up to five times.

We have plant and equipment, including our water-jet cutting machine and CNC machining center, to produce diameters between 3mm and 1500 mm, and thicknesses up to 25m.

Quartz glass according to customer's requirements, made from JGS1, JGS2, JGS3, on production.

Technical Notes:

The thickness of the various non-standard aluminosilicate glass can be customized.

Other sizes can be customized.

Copyright © Hengshui Aohong Special Glass Manufacturing Co., Ltd. All Rights Reserved | Sitemap