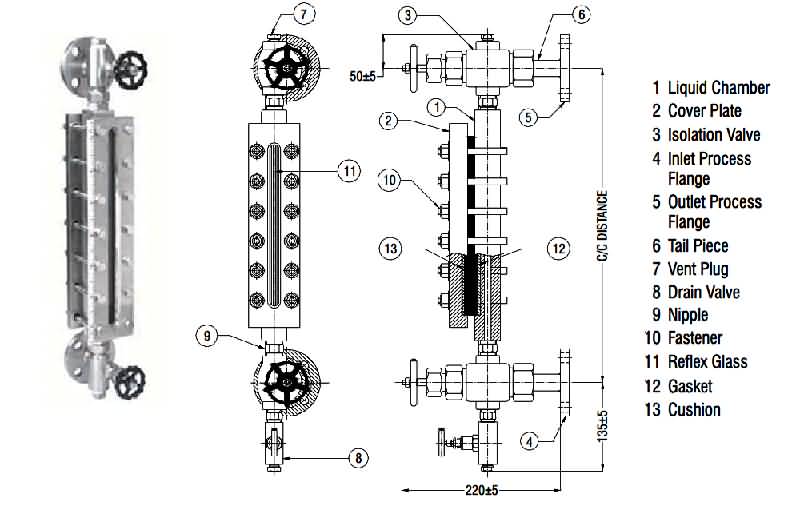

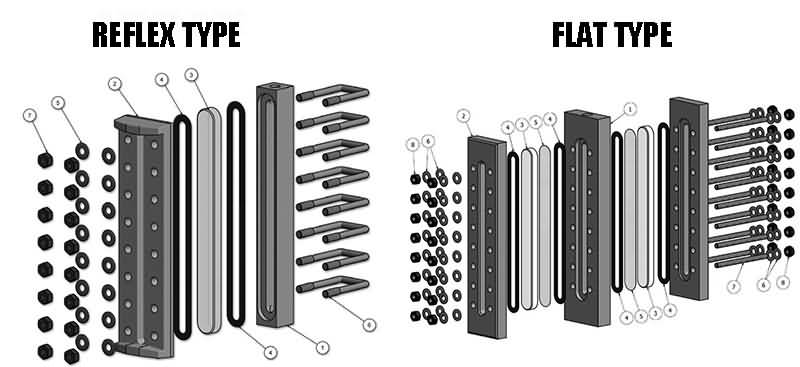

Glass Plate Type level Gauge is a common type level gauge, and the Glass plate include reflex gauge glass (Reflexion gauge glass) and transparent gauge glass(plain gauge glass or flat gauge glass). It is very important to obey the right method of level gauge installation and maintain to protect the gauge glass part.

a). Inspection method of glass plate Type level gauge

1. Remove the bolts and nuts on the glass plate level gauge, and remove the gland, gauge glass gasket, gauge glass and mica shield in order (only the level gauge for measuring alkaline medium has mica shield, in order to protect transparent gauge glass, and other reflex gauge glass type level gauge don’t have mica shield).

2. Clean the dust and oil stains on the level gauge;

3. Remove the rust on the level gauge;

4. Remove the residue of the sealing gasket in the sealing window of the level gauge, taking care not to damage the sealing surface;

5. Trim the sealing surface to make the surface roughness meet the requirements.

6. Replace with new spare parts

7. Install one piece of metal graphite gasket, one piece of mica shield in order (the level gauge for measuring alkaline medium has mica sheet, and the others do not have mica sheet), one reflex gauge glass or transparent gauge glass, and one piece of buffer metal graphite gasket And gland;

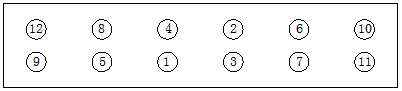

8. Tighten with fastening bolts. The fastening sequence is shown in the figure below. When fastening, the bolts must be gradually and evenly applied in sequence, using 15N. Tighten in increments of M torque, and the final sealing torque is about 100N. M.

9. Replace with a new blow down valve (if it is not damaged, it can be replaced).

10. Water pressure test (pressure test pump) and appearance inspection, water pressure test at 1.5 times the working pressure, no pressure drop for 5 minutes is qualified;

11. Dry the water in the level gauge and visually inspect the appearance.

b). Precautions for installation of glass plate level gauge

It is necessary to check whether the removed fastening bolt has thread damage, if any, it must be replaced, and the threaded part is coated with graphite powder or high temperature grease mixed with machine oil.

c). Maintenance of glass plate level gauge

1. In order to prevent corrosion of the surface of the level gauge, the surface should be kept clean and dry.

2. When using a level gauge whose temperature exceeds normal temperature, it is not advisable to open the valve immediately after installation. It should be preheated for 20-30 minutes before entering the medium after the glass plate has a certain temperature. After the glass plate level gauge has been used for a period of time, the pressure plate screw should be re-tightened. When tightening, it is clamped several times in a cross pattern of 1, 3, 5...2, 4, 6...

3. When the needle valve is opened, it should be opened gradually to prevent the steel ball in the valve from being automatically sealed by the one-way pressure of the medium and affecting the correctness of the indicated liquid level. But after the medium flow is stable, the valve should be fully opened to prevent the steel ball in the valve from being resisted by the valve clack and affecting the automatic closing of the valve when an accident occurs.

4. In order to reduce the installation stress, the actual deviation between the center distance of the two flanges of the level gauge and the center distance of the two flanges of the container should be checked during installation. If the deviation is too large, it should be adjusted and not forced to install.

5. When the temperature of 1365~1366 high medium exceeds 200℃, the working pressure must be reduced.

Copyright © Hengshui Aohong Special Glass Manufacturing Co., Ltd. All Rights Reserved | Sitemap