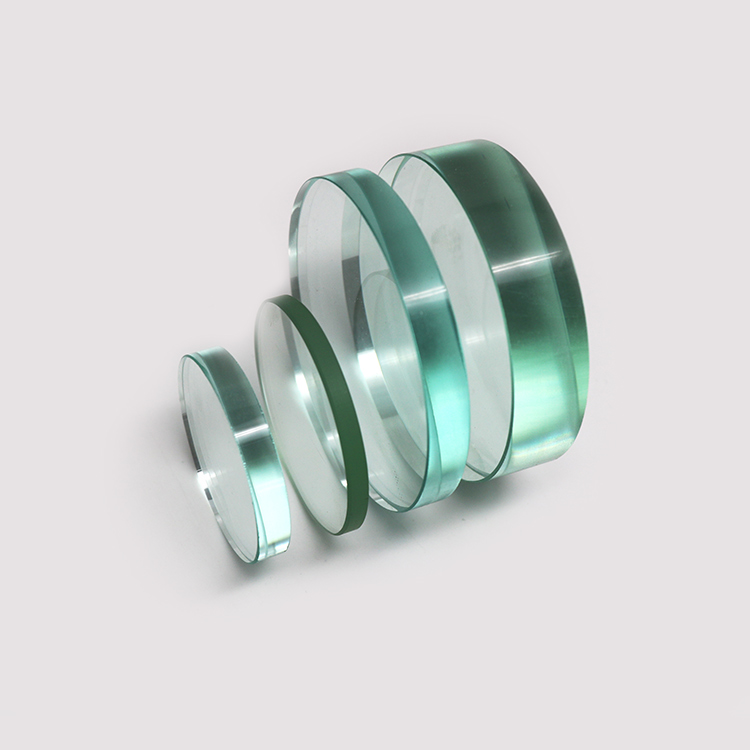

Tempered sight glasses, also referred to as tempered windows or observation windows, are critical components in various industrial and laboratory applications where visual inspection of internal processes is essential. These specialized glasses undergo a tempering process that enhances their strength, durability, and resistance to thermal shock, making them suitable for high-pressure and high-temperature environments. However, like any technology, tempered sight glasses possess both advantages and disadvantages. This article explores these aspects to provide a comprehensive understanding of this technology.

**Advantages of Tempered Sight Glasses** 1. **Enhanced Durability and Strength:** The tempering process involves heating the glass to a specific temperature followed by rapid cooling. This procedure creates a compressed surface layer that resists scratching, cracking, and breaking. As a result, tempered sight glasses exhibit significantly greater durability than ordinary glass, ensuring an extended service life while reducing maintenance costs. 2. **Thermal Shock Resistance:** In industries where equipment operates under extreme temperature fluctuations, tempered sight glasses offer superior resistance to thermal shock. They can endure rapid changes in temperature without cracking, thereby maintaining the integrity of the visual inspection window. 3. **Improved Safety:** The increased strength and durability inherent in tempered sight glasses contribute to enhanced safety for operators and personnel alike. In the event of accidental breakage, these glasses shatter into small fragments that are relatively harmless—thereby minimizing the risk of serious injury. 4. **Clear Visibility:** Designed specifically for clarity, tempered sight glasses provide clear views free from distortion regarding internal processes. This feature is crucial for real-time monitoring and troubleshooting operations—ensuring efficient production while prioritizing safety.

5.Versatility in Applications: Due to their robust nature, tempered sight glasses can be used in a wide range of applications, including chemical reactors, steam boilers, pressure vessels, and various types of process equipment. They are also available in different sizes, shapes, and configurations to meet specific requirements.

Disadvantages of Tempered Sight Glasses

Cost: Tempered sight glasses are generally more expensive than ordinary glass due to the specialized tempering process and materials used. This can be a significant consideration for budget-conscious projects or applications where the cost-benefit ratio is tightly scrutinized.

Limited Optical Clarity: While tempered sight glasses offer clear visibility, they may not match the optical clarity of some high-end materials used in specialized applications. This can be a concern in fields where precision and detail are paramount, such as advanced research or high-precision manufacturing.

Susceptibility to Stress Corrosion Cracking: Tempered glass, like any other type of glass, can be susceptible to stress corrosion cracking in certain environments. This occurs when the glass is exposed to corrosive chemicals or stress conditions that can weaken its structure over time.

Fragility in Certain Conditions: While tempered glass is significantly stronger than ordinary glass, it can still break under extreme conditions, such as high-impact forces or prolonged exposure to extremely high temperatures. This necessitates careful handling and installation to prevent accidental breakage.

Complexity in Repair and Replacement: Due to their specialized nature, tempered sight glasses can be more complex to repair or replace than standard glass components. This may require specialized tools, training, and downtime, impacting operational efficiency and cost.

In conclusion, tempered sight glasses offer numerous advantages in terms of durability, thermal shock resistance, safety, and clear visibility, making them invaluable in various industrial and laboratory applications. However, their higher cost, potential limitations in optical clarity, susceptibility to stress corrosion cracking, fragility in extreme conditions, and complexity in repair and replacement are factors that must be carefully considered when evaluating their suitability for a particular application. By weighing these advantages and disadvantages, decision-makers can make informed choices that balance cost, performance, and safety requirements.

Copyright © Hengshui Aohong Special Glass Manufacturing Co., Ltd. All Rights Reserved | Sitemap